This measure provides valuable information for cost management and decision-making, as it helps companies determine the cost of producing a good and its profitability. To total your manufacturing cost, you need to calculate the COGM by adding up the prices of raw materials, direct labor, and manufacturing overhead incurred during production. Then, add it to the purchases of raw materials made during the period and subtract it from the ending raw materials inventory, which is the number of raw materials on hand at the end of the period.

With time logs and timesheets, companies just take the number of hours worked multiplied by the hourly rate. For information on calculating manufacturing overhead, refer to the Job order costing guide. By tracking the COGM over time, a company can identify trends and patterns in its production costs and take action to reduce or control costs. Due to the nature of its business, a retail establishment does not incur any manufacturing costs because it deals exclusively in the sales of products made by others. It means it entirely comprises the fee of goods sold off the products it resells. Unlike retailers, manufacturers have unique inventory categories such as raw materials, work in process, and finished goods, all of which contribute to the calculation of the cost of goods manufactured.

Step 3: Calculate manufacturing overhead

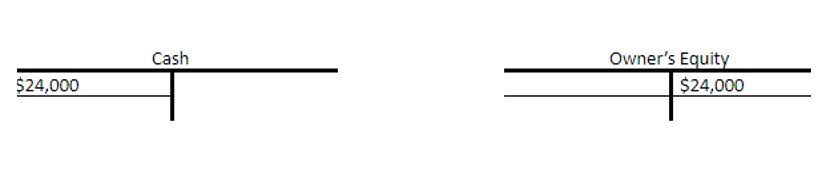

The cost of goods manufactured (COGM) refers to all the costs involved in producing a product, including direct labor, indirect labor, raw materials, and overhead costs. In order to determine the actual direct materials used by the company for production, we must consider the Raw Materials Inventory T-account. Raw materials inventory refers to the inventory of materials that are waiting to be used in production. For example, if a company were to make a raw material purchase for use, these would be recorded in the debit side of the raw materials inventory T-Account. The Cost of Goods Manufactured (COGM) is a fundamental metric in the financial management of manufacturing companies. It provides a clear picture of the total production costs and is vital for various financial decisions.

The beginning work in progress (WIP) inventory balance for 2021 will be assumed to be $20 million, which was the ending WIP inventory balance from 2020. In this article, we review the subtleties surrounding promotion conversations in modern companies. To equip people to start or manage these critical conversations, we explore the dos and don’ts, give practical advice, and offer actionable insights.

Cost of Goods Manufactured in Accounting and Finance

The COGM formula starts with the beginning-of-period work in progress inventory (WIP), adds manufacturing costs, and subtracts the end-of-period WIP inventory balance. The Cost of Goods Manufactured (COGM) represents the total costs incurred in the process of converting raw material into finished goods. Cost of Goods Manufactured (COGM) and Cost of Goods Sold (COGS) are two closely related financial metrics in accounting that provide essential information about the cost of producing and selling a product. The origin of this term dates back to management accounting practices in 1920s America, when businesses began tracking costs related to production more closely than ever before. Examples of manufacturing overhead costs include utilities, rent, insurance, depreciation, property taxes, and equipment maintenance.

- It is also known as the cost of goods completed and it is part of the cost of goods sold.

- But sales revenue only tells part of the story; you also have to factor in the costs of generating your inventory in the first place.

- If your COGM is higher than your selling price, then you aren’t making a profit on each item sold — and this can be bad news for your business.

- You can reduce workers’ wages and salaries and hourly rate or make them more efficient in their work, simultaneously boosting the credit side of the balance sheet.

- It helps calculate the cost of goods sold, which is used to calculate gross profit.

- The COGM amount is transferred to the finished goods inventory account during the period and is used in calculating cost of goods sold on the income statement.

- The origin of this term dates back to management accounting practices in 1920s America, when businesses began tracking costs related to production more closely than ever before.

Without knowledge of COGM, it is almost impossible for a manufacturer to reduce costs and boost profitability. The initial work in progress (WIP) inventory of a corporation consists of the value of goods still being produced. At the end of one business period or the start of another, this value can be exactly established.

Products

This is the cost value of the raw materials inventory at the start of the accounting period. This statement includes a list of all raw materials that are awaiting use in manufacturing. COGM, on the other hand, is a gauge of the manufacturing costs during a specific time period. TMC calculations only include direct material costs because they do not include indirect material or factory overhead expenses. COGM is a useful accounting metric because it can be used to measure the performance of production and manufacturing costs with target costs.

A COGM schedule is a detailed statement or report that outlines the various components contributing to the total cost of goods manufactured during a specific accounting period. The various components comprise the cost of goods manufacture (COGM), including direct labor costs, direct material costs, and factory overheads. We add the sum total of all three components to the net finished goods inventory, calculated by subtracting the closing work-in-progress goods inventory from the opening work-in-progress inventory. Understanding how to calculate the cost of goods manufactured correctly is essential in accounting and finance as it helps businesses determine their gross profit margin for each product produced. It includes calculating all manufacturing-related expenses such as raw materials, labor wages, factory overhead expenses, depreciation on machinery or equipment used in production, etc. The cost of manufacturing overhead refers to the indirect costs incurred during the production process, such as indirect materials, indirect labor, and indirect expenses.

In the manufacturing industry, COGM indicates how much it costs to produce a particular product. Before we delve into the COGM formula, reference the formula below that calculates a company’s end-of-period work in progress (WIP) balance. WIP represents any partially-complete inventory that is not yet marketable, i.e. they have not yet become finished products ready to be sold to customers. Prior to discussing how to calculate the cost of goods manufactured(COGM) also known cost of goods manufactured calculator as cost of goods completed, we must first know and understand what it is and what it entails. Martin loves entrepreneurship and has helped dozens of entrepreneurs by validating the business idea, finding scalable customer acquisition channels, and building a data-driven organization. During his time working in investment banking, tech startups, and industry-leading companies he gained extensive knowledge in using different software tools to optimize business processes.

It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel. For example, a producer might purposely start producing units earlier in anticipation of rising seasonal demand. The cost of goods sold (COGS) and cost of goods manufactured (COGM), despite sharing similar labels, are not the same. Don’t forget to take employee payment agreements and overtime expenses into consideration. Management can evaluate each component of the COGM formula when it is fully aware of what a company is generating. Mattias is a content specialist with years of experience writing editorials, opinion pieces, and essays on a variety of topics.